In the industrial world, the selection of parts to manufacture certain components is essential to ensure the efficiency, safety, and durability of systems. Among these, ball valves for the industry play a key role.

Design of Industrial Ball Valves

Our industrial ball valves are specially designed to operate under high-pressure conditions and are available in various sizes. This robust design ensures reliable performance where other types of valves might fail. All our valves are manufactured under the strict DIN and ANSI standards, ensuring global quality and compatibility.

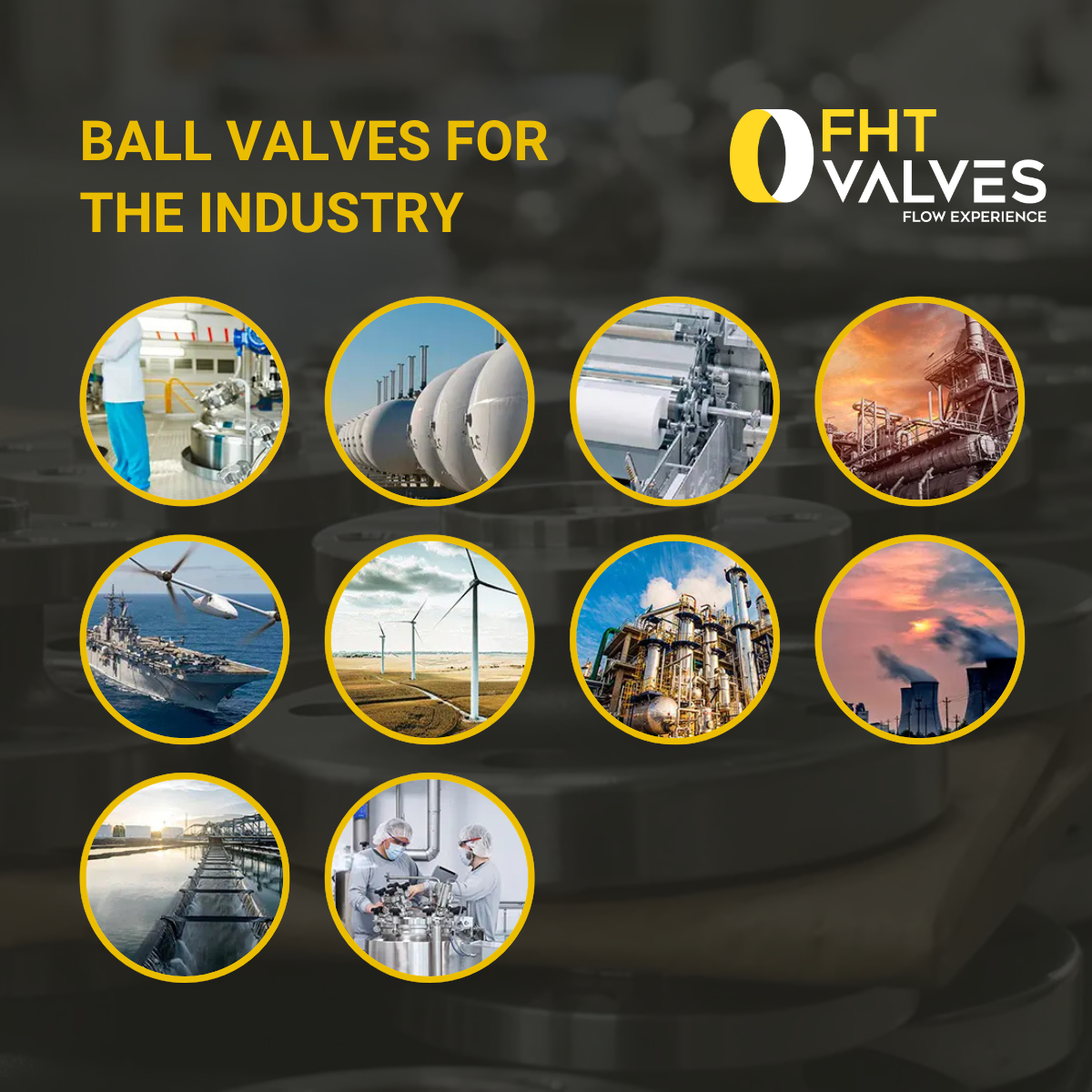

Types of Valves for Various Industries

We offer a wide range of ball valves to meet the specific needs of industry:

- Industrial ball valves: including bronze valves, soft-seated floating valves, metal-to-metal floating valves, soft-seated trunnion valves, and metal-to-metal trunnion valves.

- Specialized products: the range extends to integral seat valves, spring-loaded seat ball valves, tank bottom valves, 3-way valves, oxygen valves, severe service valves, hydrogen valves, DBB valves, and wafer-type valves.

- Custom valves: we understand that each project may have unique requirements. That’s why, at FHT, we offer maximum customization, including the option to adapt the color of external components for perfect aesthetic integration or for specific identification purposes in your facility.

International Certifications for Industrial Ball Valve Manufacturing

The reliability and operational efficiency of FHT valves are backed by major international certifications, ensuring top quality and long service life:

- API 6D

- Fire Safe

- ISO 9001

- SIL 3

FHT valves are the smart choice for any industrial environment demanding reliability, durability, and efficiency. Their commitment to the highest manufacturing standards and a broad range of products, supported by key certifications, ensures that your investment in FHT valves results in smooth and safe operations.