Industrial valves are essential components in a wide variety of applications in the world of engineering and industry. These key parts control the flow of liquids, gases and other media in industrial processes, ensuring efficient and safe operation. In this article, we will explore the different aspects related to industrial valves, from their variety of types to their importance in design and selection, maintenance, regulations, technology and future trends in this industry.

Industrial Valves Types

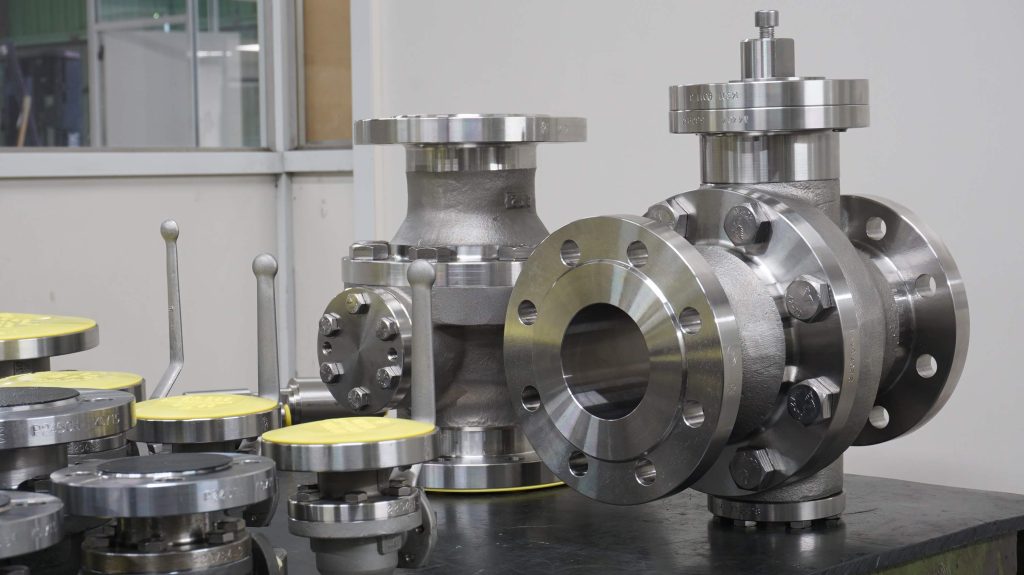

Industrial valves come in a wide range of types, each designed to meet specific requirements in different industrial applications. Some of the most common types include:

Gate Valves

These valves are ideal for flow control in high pressure applications. Their gate design allows full or no flow and are commonly used in water and gas systems.

Globe Valves

Globe valves are versatile and are used in a variety of applications, including flow regulation and tight shut-off. They are especially useful in temperature and pressure control applications.

Butterfly Valves

These valves are lightweight and economical. Their flat disc butterfly design allows for fast flow control, but are ideal for low pressure applications.

Ball valve

Ball valves are known for their ball design that allows fast and accurate flow control. They are widely used in the chemical and petrochemical industry.

Diaphragm Valves

Diaphragm valves are excellent for applications involving highly corrosive media. They use a diaphragm to control flow and prevent media contamination.

Needle Valves

Needle valves offer extremely precise flow control and are used in applications requiring fine regulation, such as the pharmaceutical industry.

Check Valves

These valves allow flow to go in a specific direction and prevent backflow. They are essential to prevent backflow in systems that transport liquids or gases.

These are just a few examples of the types of industrial valves available. Choosing the right type depends on the specific needs of the application, making selection and design critical considerations.

Importance of Valve Design and Selection

Proper design and selection of industrial valves is critical to ensure efficient and safe operation in any industrial application. Choosing the wrong valve can result in flow problems, loss of efficiency and, in the worst case, safety hazards.

The valve design must be adapted to the specific operating conditions, such as pressure, temperature, media type and flow rate. In addition, aspects such as corrosion, erosion and chemical resistance must be considered. Choosing the right material of construction is essential to ensure the durability and service life of the valve.

Valve selection must also take into account the regulation and control aspects required in the application. The valve’s ability to provide precise flow control is crucial in many industries, such as chemical and pharmaceutical.

Maintenance and Conservation

Proper maintenance of industrial valves is essential to ensure their optimum performance over time. Maintenance can range from regular inspections to scheduled repairs and replacements.

The frequency and nature of maintenance depends on factors such as the type of valve, operating conditions and the medium conveyed. Gate valves and globe valves, for example, may require more frequent maintenance due to their design and use in high pressure applications.

Maintenance may include inspection of seats, packing, actuators and internal components. It is essential to detect and address any leaks or wear early to avoid more serious and costly problems in the future.

Standards and Regulations

Industrial valves are subject to specific regulations and standards, which vary by industry and geographic location. These regulations are designed to ensure safety and quality in industrial applications.

It is important for industrial valve companies to keep abreast of and comply with the relevant regulations. This is not only essential for the safety of workers and the environment, but can also have a significant impact on companies’ legal liability.

Some of the common regulations include design, testing and material standards, as well as labeling and documentation requirements. Valves used in critical applications, such as the nuclear industry or the food industry, are subject to stricter regulations.

Technology in Industrial Valves

Technology plays an increasingly important role in the development and improvement of industrial valves. Technological innovations allow for more precise control, greater efficiency and real-time monitoring of operating conditions.

Some of the most prominent technologies in this area include:

Intelligent Actuators

Intelligent actuators allow precise, automatic control of valves based on operating conditions. They can be programmed to respond to changes in pressure, temperature or flow rate autonomously.

Integrated Sensors

The incorporation of sensors in the valves allows continuous monitoring of variables such as pressure, temperature and flow rate. This provides real-time data that can be used for control and decision making.

Solenoid Valves

Solenoid valves allow precise regulation through electrical signals. This is especially useful in applications where fine and fast flow control is required.

Connectivity and Remote Control

Connectivity through the cloud enables remote control of valves and real-time data collection. This is especially valuable in distributed applications or remote monitoring systems.

The technology not only improves efficiency and accuracy in valve control, but also facilitates preventive maintenance and early detection of problems.

Future Trends in Industrial Valves

The world of industrial valves is constantly evolving, and several trends are shaping the future of this industry. Some of the most notable trends include:

Sustainability

Growing environmental awareness is driving demand for more energy-efficient industrial valves that reduce greenhouse gas emissions.

Internet of Things (IoT)

Integrating industrial valves into IoT systems enables real-time monitoring and data-driven decision making. This improves efficiency and reduces operating costs.

Additive Manufacturing

Additive manufacturing, such as 3D printing, is revolutionizing the way valves are produced, enabling more complex and customized designs. In addition, manufacturing lead times can be shortened dramatically.

Advanced Materials

The development of more corrosion and erosion resistant materials is expanding the applications of industrial valves in extreme environments.

Automation and Robotics

Automation and robotics are driving the demand for industrial valves that are easily integrated into automated systems.

FHT Valves, Industrial Valves Suppliers

When it comes to purchasing high quality industrial valves, it is essential to have reliable and experienced suppliers. In this regard, FHT Valves stands out as one of the leading suppliers of industrial valves in the market.

FHT Valves has a wide range of products covering different types of industrial valves. Their commitment to quality, innovation and customer service has made them a reliable partner for companies in various industries.

FHT Valves provides expert technical advice to help customers select the right valves for their specific applications. They also excel in customer service and after-sales support, ensuring that valves perform optimally throughout their service life.

Industrial valves play a crucial role in a wide variety of industrial applications, and their proper selection, design and maintenance are critical to ensure efficient and safe operation. Regulations, technology and future trends in this industry are constantly evolving, and having reliable suppliers like FHT Valves is essential to the success of any company that relies on these critical parts.