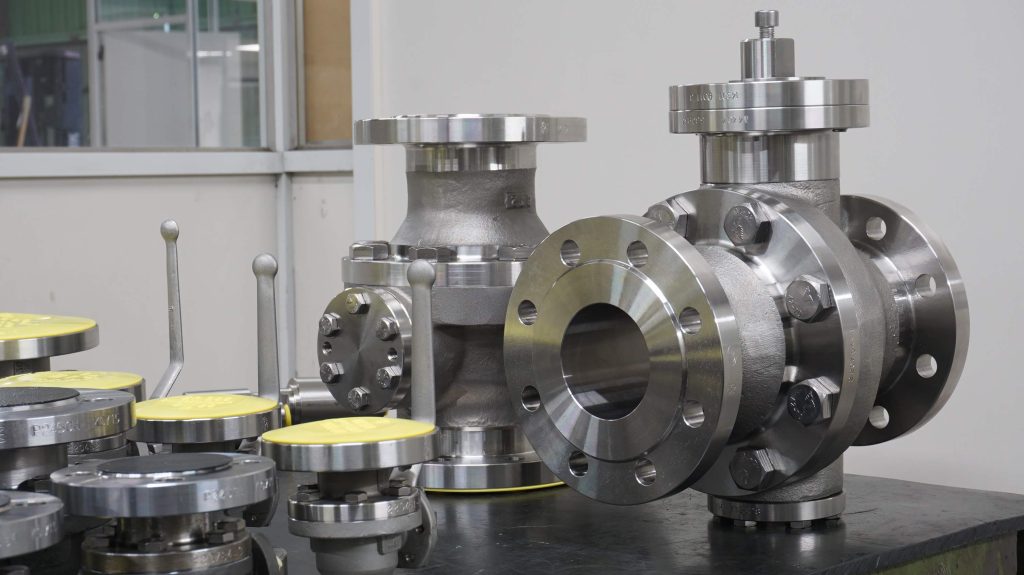

Ball valves are a type of valve that uses a perforated ball to control the flow of liquids and gases through a piping system. The ball is attached to a shaft (in the case of the guided ones also the trunnion) that allows it to rotate, and when in closed position, the ball blocks the fluid flow.

However, within the category of ball valves, there are several types with specific characteristics and applications. In the following, we will describe several types of ball valves.

Top inlet ball valve

Top entry ball valves have maintenance access at the top of the valve body. This allows the valve to be repaired without having to remove it from the system and is widely used for welded ends and gas applications. They are also ideal for applications where space is limited.

Floating ball valve

Floating ball valves do not have a trunnion to support the ball at the bottom. Floating balls allow better sealing and less wear on the valve seat. These valves are commonly used in low pressure applications.

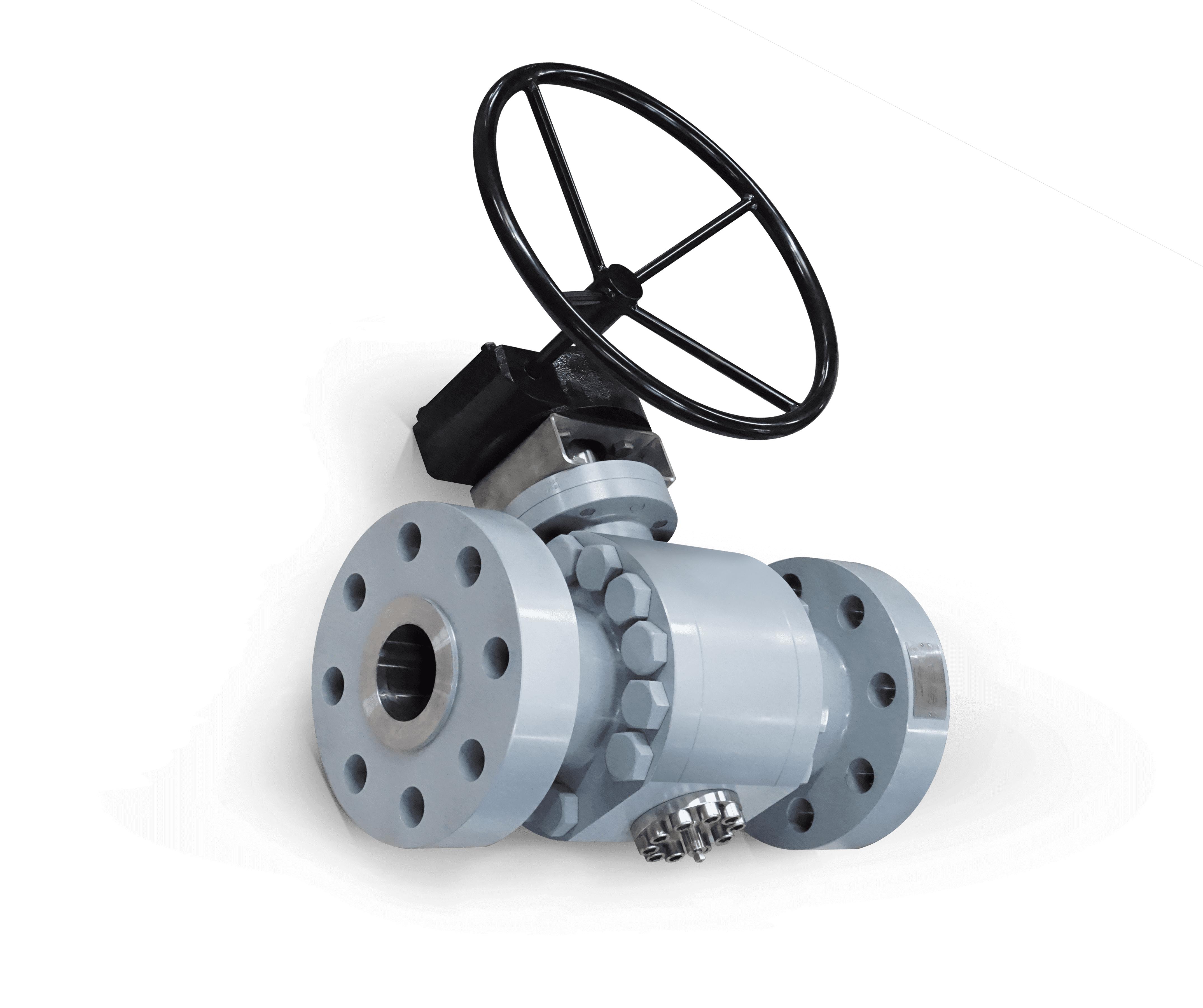

Trunnion or guided ball valves

Guided ball valves have a trunnion that prevents the ball from moving at the bottom. This guide or trunnion is connected to the lower end of the valve body. This allows the ball to rotate without friction and provides a better seal. Guided or trunnion ball valves are commonly used in high pressure and high temperature applications. In this publication we want to show you up to 8 types of ball valves.

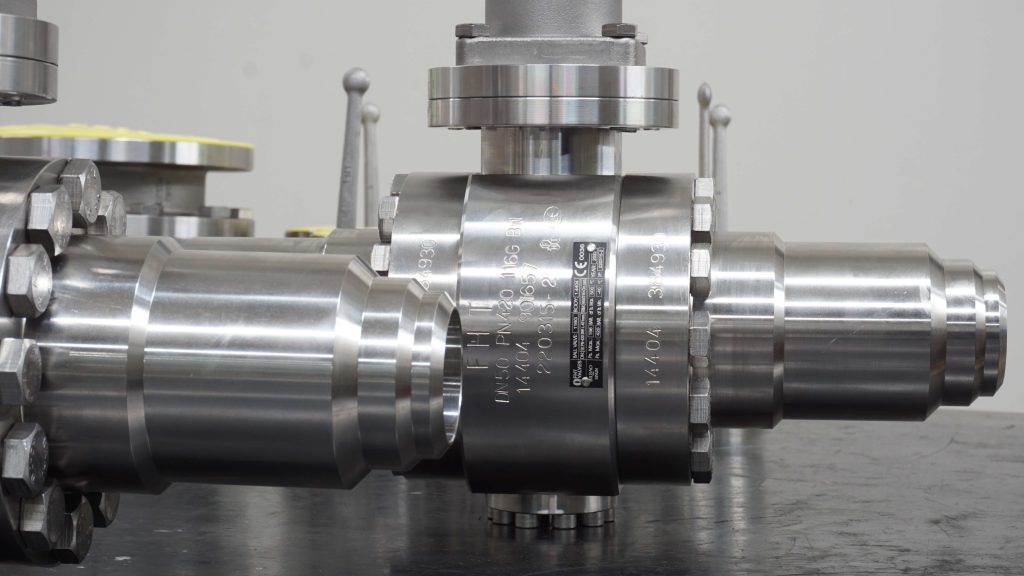

Double block and bleed valve

Double block and bleed valves normally have two balls in a single valve body. This allows, in addition to upstream and downstream sealing, simultaneous blocking and venting of the two valve sections for maintenance and repair. They are ideal for applications where complete cleanliness of the process line is required, such as preventing product contamination, calibration, fluid transmission and storage.

FHT relies on a guided ball design with offset seats on both sides as well as holes for venting and venting.

Side inlet ball valvel

In side inlet ball valves, in the valve assembly the ball is mounted sideways to the valve body. In general, side inlet ball valves are more economical than top inlet valves. This type of side entry design is a good choice for high pressure applications.

Orbital valve

Orbital valves have a ball that rotates around an eccentric axis, which means that in addition to rotating 90º like all balls, it then moves allowing for better sealing and precise flow control. They are ideal for applications where a high degree of accuracy and flow control is required.

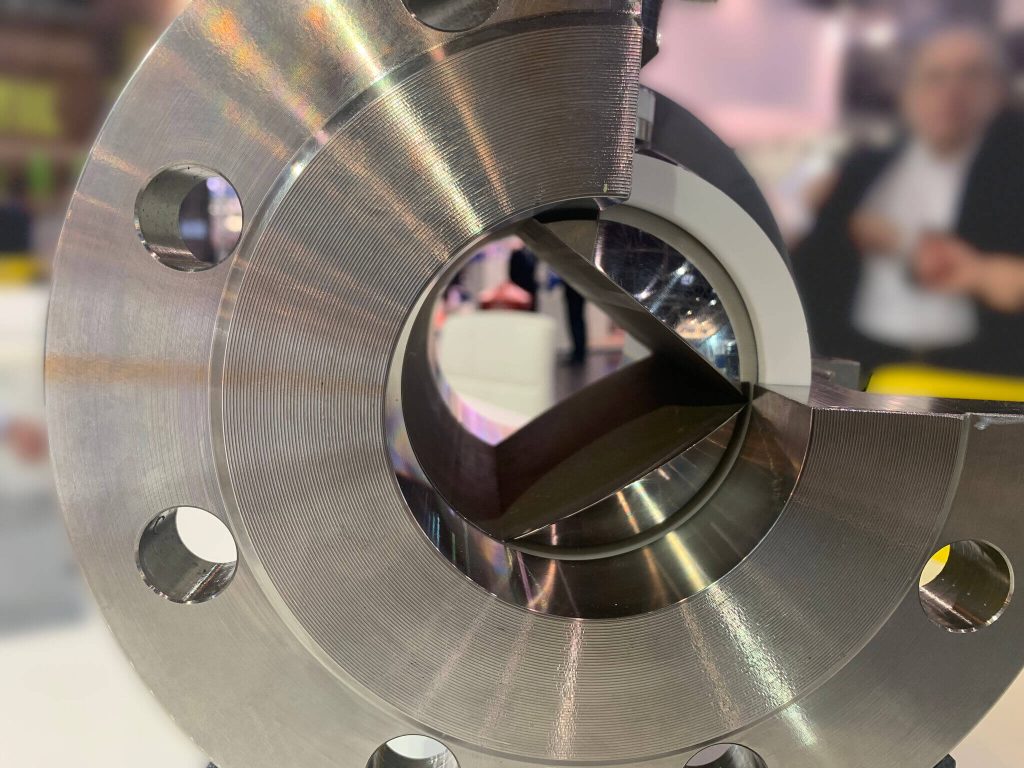

V bore ball valve

V-pitch ball valves are similar to a conventional ball valve, but with a contoured V-notch segment in the ball instead of a sphere. This notch can be supplied in various degrees (15º, 30º, 60º…). It can be used as a regulating valve and is available in a wide range.

Forged ball valve

Forged ball valves are machined directly from round or bar stock, which avoids porosity and other casting defects. They are also stronger and more durable than cast ball valves. They are ideal for high pressure and high temperature applications and are less prone to damage from impact or vibration.

In conclusion, there are several types of ball valves with specific characteristics and applications. The choice of the appropriate type of ball valve will depend on the specific needs.