Ball valves represent one of the most effective mechanisms for regulating the flow of liquids and gases in industrial applications. Their structure is based on a perforated sphere that acts as the control element, allowing or blocking flow depending on its position. This mechanical component stands out for its straightforward design and remarkable operational efficiency.

Industrial Applications of Ball Valves

Industrial processing sector

In manufacturing plants, these valves play a crucial role in fluid management during production. Their ability to provide precise control makes them indispensable in:

- Food production lines

- Beverage manufacturing

- Chemical manufacturing processes

Their quick actuation allows instant adjustments in flow rates, optimizing production processes.

Chemical and petrochemical industries

These sectors present extremely demanding operating conditions, where resistance to corrosive agents is essential. Ball valves made with specialized materials offer:

- Superior corrosion resistance

- Completely tight sealing

- Prevention of hazardous leaks

- Safety in handling toxic substances

Food and pharmaceutical sectors

The food and pharmaceutical industries require exceptional hygiene standards. Stainless steel ball valves provide:

- Ease of cleaning and sterilization

- Corrosion resistance

- Prevention of cross-contamination

- Compliance with strict sanitary regulations

Main Benefits

Ball valves offer numerous technical and operational advantages:

Simplicity of design

The minimalist design of these valves ensures a long service life and significantly reduces maintenance requirements. Their straightforward construction minimizes potential failure points.

Quick operation

The opening and closing mechanism operates with exceptional speed, allowing immediate responses to process changes. This feature is vital in applications where response time is critical.

Perfect sealing

Once closed, these valves provide total isolation of the flow, eliminating any possibility of leakage. This property is especially valuable when handling hazardous or costly substances.

Resistance to harsh environments

The availability of multiple construction materials allows selecting the most suitable valve for each specific environment, ensuring optimal performance even under adverse conditions.

Dimensional versatility

The market offers a wide range of sizes and configurations, from miniaturized units for laboratory applications to large-scale industrial models for massive processing facilities.

- Automation compatibility They can operate manually or through electric, pneumatic, or hydraulic actuators, adapting to local or remote control systems.

Operating Principle of Ball Valves

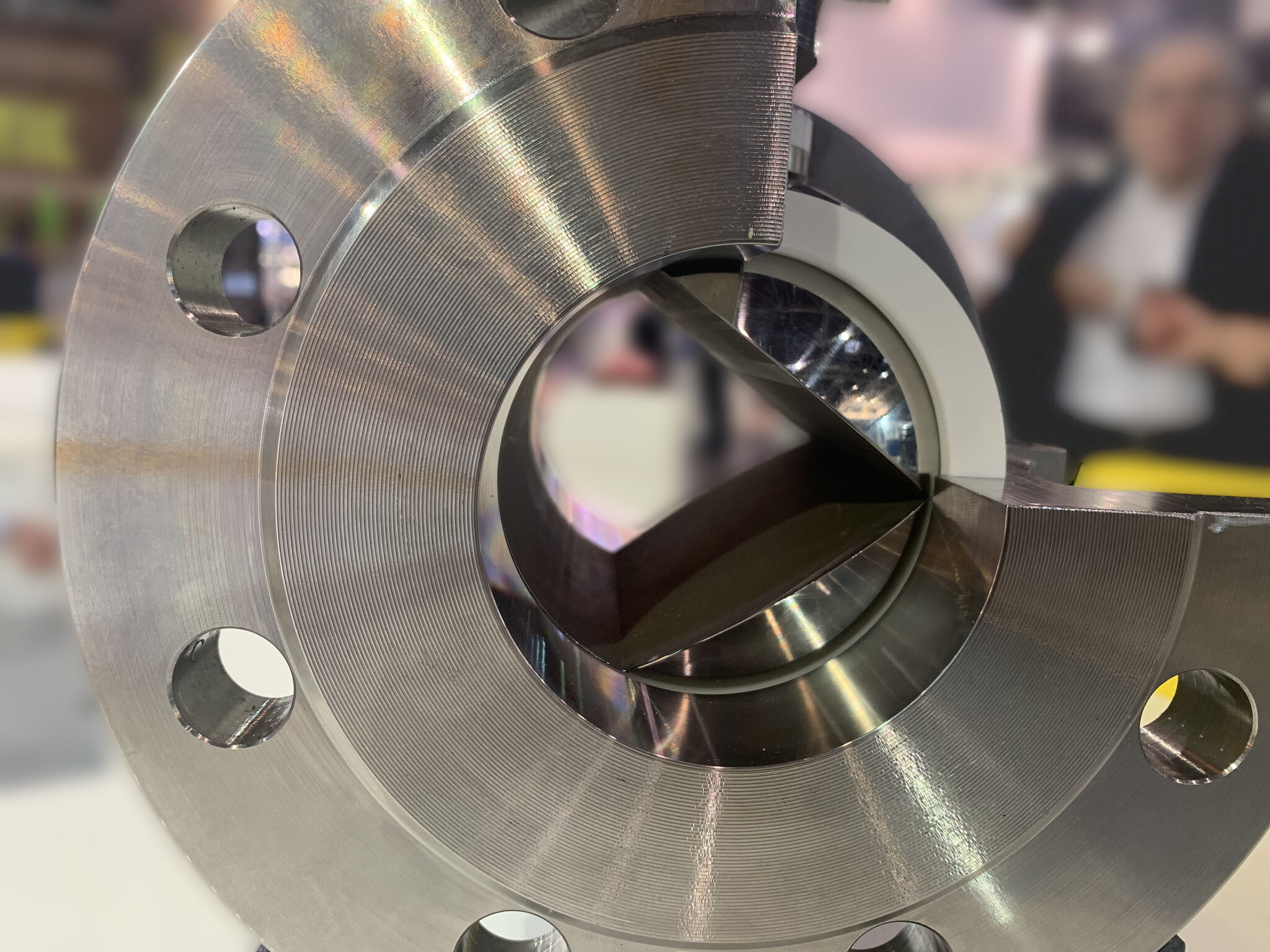

The operation of this mechanism is based on a simple yet highly effective principle for fluid control. The valve incorporates the following main components:

- Main body: The external structure that houses and protects all the internal elements of the valve. It is generally made of metallic materials resistant to pressure and corrosion, such as stainless steel, brass, or specific alloys, depending on the application. The body has inlet and outlet ports through which the fluid flows.

- Perforated sphere: Inside is a ball or sphere with a through-hole in its center. This hole allows fluid to flow when aligned with the inlet and outlet ports of the body. By rotating the sphere 90 degrees, the hole becomes perpendicular to the passage and completely blocks flow. This simple quarter-turn movement makes the valve a quick open/close device.

- Stem: A shaft that connects the perforated sphere with the external actuator. The stem transmits the torque generated by the actuator and allows the sphere to rotate within the valve seat. It also incorporates sealing joints that prevent external leaks and ensure tightness around the shaft.

- Actuator: The system that drives the rotation of the sphere. It can be:

- Manual: via a lever or handwheel, directly operated by the user.

- Electric: via an electric motor that rotates the stem.

- Pneumatic: using compressed air pressure that moves a piston or rotary mechanism.

- Hydraulic: powered by hydraulic fluid pressure. The actuator defines the type of control, which can be local (manual) or remote (automated).

The actuator defines the control method and allows either manual or automated operation according to the installation’s needs.

Main Types of Ball Valves

Several designs are used in the industry depending on the application:

- Floating: The ball is supported only by the stem and “floats” between the seats. This design is common for small diameters and moderate pressures. The fluid pressure helps push the ball against the downstream seat to seal. Its advantage is simplicity and low cost, but it is not ideal for high pressures or large diameters, as the free ball generates higher torque and only seals on one side.

- Trunnion-mounted: The ball is anchored at the top by the stem and at the bottom by a shaft or pivot called a trunnion. This design secures the ball, reducing the load on the seats. Thanks to spring-loaded seats, it seals effectively at both low and high pressures. Suitable for high pressures and large diameters, as the trunnion absorbs extra force, maintaining seals on both sides and requiring less torque.

- Top-entry: Access to the ball, seats, and stem is through the top of the body by removing a cover, without disassembling the valve from the pipeline. This design facilitates “in-situ” maintenance: seals can be replaced, or the ball removed without stopping the installation. Used in demanding industrial applications where quick service is critical (oil, petrochemical, etc.).

- Side-entry: The body is split horizontally; maintenance usually requires removing the valve from the process. Unlike top-entry, it is heavier and more expensive, but its robust construction is preferred for extremely high pressures. Maintenance of a side-entry valve involves disassembling both halves of the body, while top-entry avoids removing the entire valve.

There are also multi-port valves (3 or 4 ways) with “T” or “L” holes in the ball, allowing switching or mixing of flows depending on the rotation position.

The housing and ball materials are chosen depending on the fluid, temperature, and pressure. The most common body materials are brass, stainless steel (especially 304 and 316), carbon steel (or coated carbon steel), cast iron, and plastics such as PVC or PP/PVDF. The ball is usually made of chrome-plated steel, chrome-plated brass, or stainless steel. Typical seats are PTFE or other polymers, except for special metal-seated valves.

| Material | Characteristics and applications |

| Brass | Widely used in plumbing, drinking water systems, compressed air, and HVAC. Withstands pressures up to ~55 bar (≃800 psi) and temperatures up to ~160 °C. Nickel-plated or lead-free versions are common for drinking water. Sensitive to chlorides or demineralized water (dezincification-resistant brass should be used). |

| Stainless steel | (Series 304/316) Suitable for humid or corrosive environments (chemical, marine, food). Withstands high pressures (~70 bar) and temperatures up to ~220 °C, with excellent durability and easy cleaning. More expensive and heavier than brass, and not suitable for concentrated hydrochloric acid or bromine. |

| Carbon steel | More economical than stainless steel. Used in oil, gas, and petrochemical industries for high pressure and temperature (often forged or coated). Requires external corrosion protection (paint, galvanizing). |

| Cast iron | Robust and inexpensive, used in water networks, HVAC, and steam (suitable up to ~40 bar, 120 °C). Fragile and heavy (can break under shock or overpressure). |

| PVC / Plastics | Plastics such as PVC, CPVC, or PVDF are lightweight and highly resistant to chemical corrosion (acids, alkalis, chlorinated water). Used in drinking water, swimming pools, and aggressive chemical processes. Limitation: withstand low pressures (≤16 bar) and temperatures (≲60 °C); not resistant to strong aromatic or chlorinated hydrocarbons. |

The choice of material depends on the medium (corrosiveness, particles, etc.), temperature, and pressure. For example, chlorinated water uses PVC or 316 stainless steel; crude oil uses forged carbon steel with coating. Chemical compatibility (selecting based on resistance charts) and sanitary regulations (e.g., lead-free materials for potable water) are key.

Main Limitations of Industrial Valves

Despite their advantages, ball valves have certain limitations:

- Not ideal for precise flow control or linear modulation (except special V-port designs).

- Soft seats may lose tightness under extreme conditions.

- Floating valves are not suitable for high pressures or large diameters.

- Handling fluids with solids can damage seats or block operation.

- Quick closure can cause water hammer.

- The lifespan of seals and packings requires periodic monitoring.

Maintenance:

Although ball valves are robust, a preventive maintenance program is recommended.

- Perform regular visual inspections (e.g., quarterly) to detect external leaks in stem or body, corrosion, or loose parts.

- Fully cycle the valve (turn it fully open and closed) periodically to prevent seizing, especially in rarely used valves.

- The body must be cleaned by removing sediments or scaling, internally and externally, using solvents compatible with the materials.

- Apply proper lubrication to the stem and moving parts according to the manufacturer’s recommendations to maintain smooth rotation. Finally, replace worn seals and packings when persistent leaks appear. In three-piece valves, seats can be replaced without removing the whole valve; in one- or two-piece designs, full replacement may be required if seats fail.

Standards and Certifications for Ball Valves

Technical standards and certification processes establish the fundamental criteria governing the design, manufacturing, evaluation, and categorization of ball valves in the industrial field. These regulatory frameworks ensure components meet the necessary requirements for operational safety, reliable performance, and technical compatibility for implementation in various work environments. Standards such as ANSI B16.10 and ANSI B16.34 in the U.S. context, as well as DIN standards (Deutsches Institut für Normung), including DIN 3202 for installation dimensions and DIN 3840 for general design and performance requirements, provide specific guidelines standardizing technical aspects of ball valves internationally.

Knowledge of international technical specifications such as API 608, ISO 17292 and ASME B16.34, along with awareness of certification protocols including ISO 9001 and CE marking, is essential for selecting valves that meet the specific requirements of each industrial application.