In the competitive world of fluid control systems, efficiency, durability and safety are critical to the success of any industrial installation. Spring-loaded seated ball valves represent a significant advance in valve technology, offering substantial advantages over conventional designs. At FHT Valves we pride ourselves on presenting cutting-edge solutions that transform the performance of your systems.

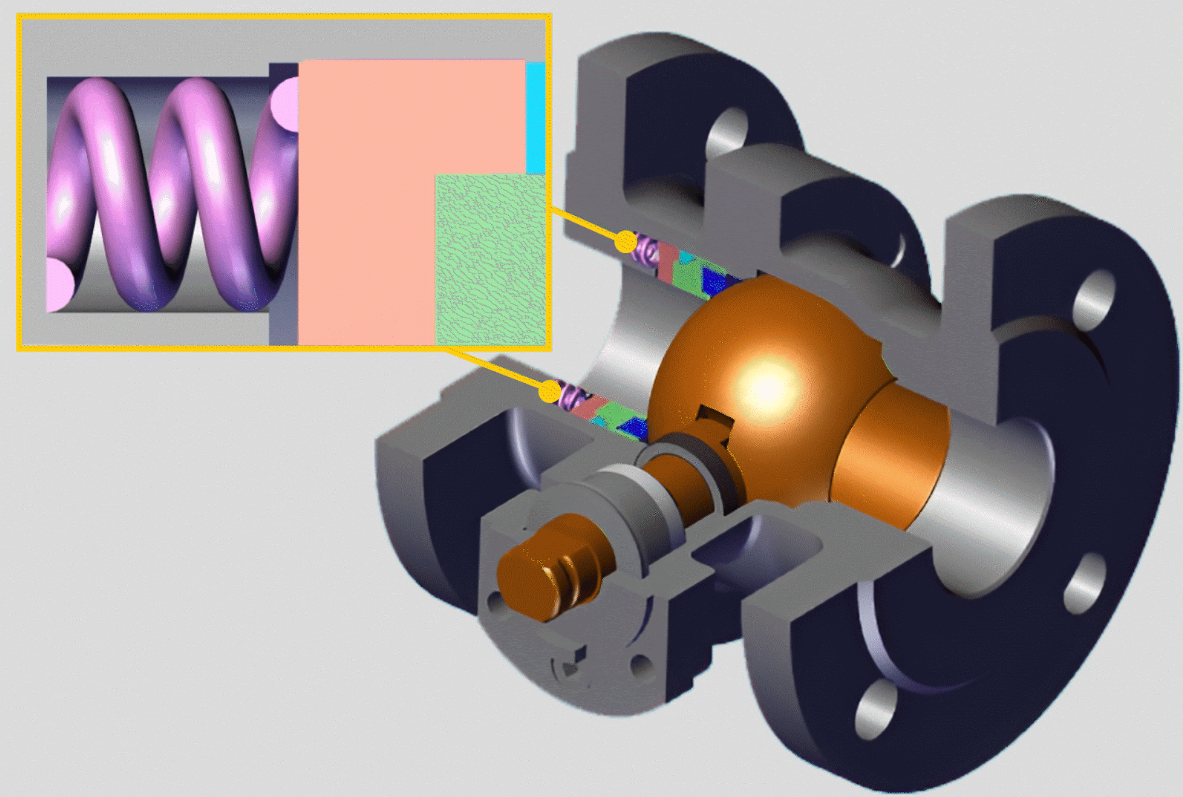

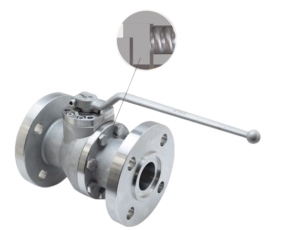

What are spring-loaded seated valves?

Spring-loaded seated valves are an advanced type of ball valve that incorporates seats made of special compensated materials and a spring preloading system. This configuration provides a constant pressure between the seat and the ball, creating a tight seal even under varying pressure and temperature conditions.

Benefits of using spings in the design of our valves

1. Exceptional bi-directional sealing

Unlike conventional valves, our spring-loaded valves guarantee tight shut-off in both flow directions. The spring system maintains a constant pressure on the ball, regardless of the fluid direction, resulting in:

- Leakage elimination even at low pressures

- Increased protection against cross-contamination

- Reliable operation in critical applications

2. Automatic wear compensation

Wear is inevitable in any mechanical component, but our valves are designed to counteract it:

- Springs automatically adjust seat position to compensate for natural wear and tear

- Sealing integrity is maintained throughout the life of the valve

- Significantly reduces the need for maintenance and readjustments

3. Superior resistance to thermal cycling

Temperature fluctuations represent a considerable challenge for most valves. FHT Ball Valves’ spring-compensated seats are noted for: Wear is inevitable in any mechanical component, but our valves are designed to counteract it:

- Ability to absorb thermal expansion and contraction without compromising the seal

- Consistent performance from cryogenic temperatures to high temperature applications

- Elimination of structural stresses caused by repeated thermal cycling

4. Longer service life under demanding conditions

Our valves are designed to excel in the most challenging environments:

- Advanced compensated materials offer superior abrasion resistance

- Spring configuration reduces friction during operation

- Wear is minimized at critical contact points

- Service life significantly extended even in applications with aggressive fluids

5. Optimized performance at low pressure

Many conventional valves have difficulty maintaining an effective seal at low pressure. FHT Ball Valves’ spring balanced seat valves eliminate this problem:

- Spring preload ensures constant contact between ball and seat

- Hermetic sealing is achieved even in vacuum or near-zero pressure conditions

- Eliminates the need for secondary sealing systems

6. Smooth operation and lower drive torque

Despite their exceptional sealing capability, our valves require less effort to operate:

- Optimized design reduces friction between components

- Lower drive torque required, even at high pressures

- Smooth operation reduces actuator wear and increases control accuracy

7. Versatility in various industrial applications

FHT Ball Valves’ spring balanced seat valves are exceptionally versatile:

- Compatible with a wide range of fluids, from cryogenic gases to corrosive chemicals

- Available in multiple configurations to suit specific requirements

- Certified for use in demanding industries such as petrochemical, pharmaceutical and food industries

Where can spring loaded ball valves be used?

Our customers in various industries have experienced significant improvements by implementing spring balanced seat valves from FHT Ball Valves:

- Petrochemical refinery: up to 85% reduction in downtime for valve maintenance

- Pharmaceutical plant: complete elimination of cross-contamination on critical production lines

- Food processing: increased valve life in applications with frequent temperature changes

Offset seat ball valves represent the state of the art in fluid control technology. Their innovative design, advanced materials and exceptional performance make them the ideal choice for applications where reliability, durability and safety are priorities.

At FHT Valves, we continue to innovate to deliver solutions that not only meet but exceed the expectations of our most demanding customers. Contact our team of experts today to discover how our spring balanced seat valves can transform the efficiency and reliability of your operations.