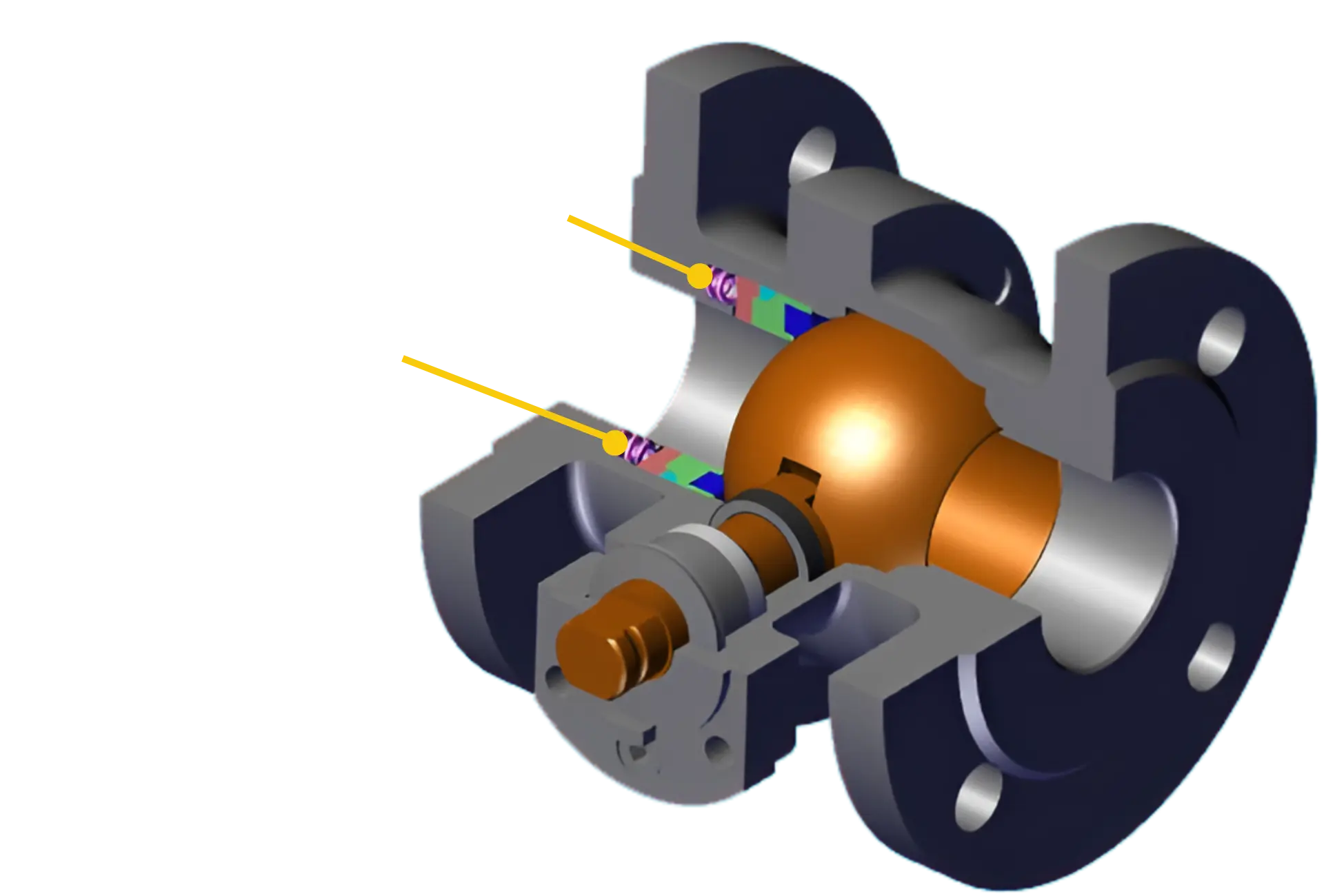

Spring-loaded seated ball valves

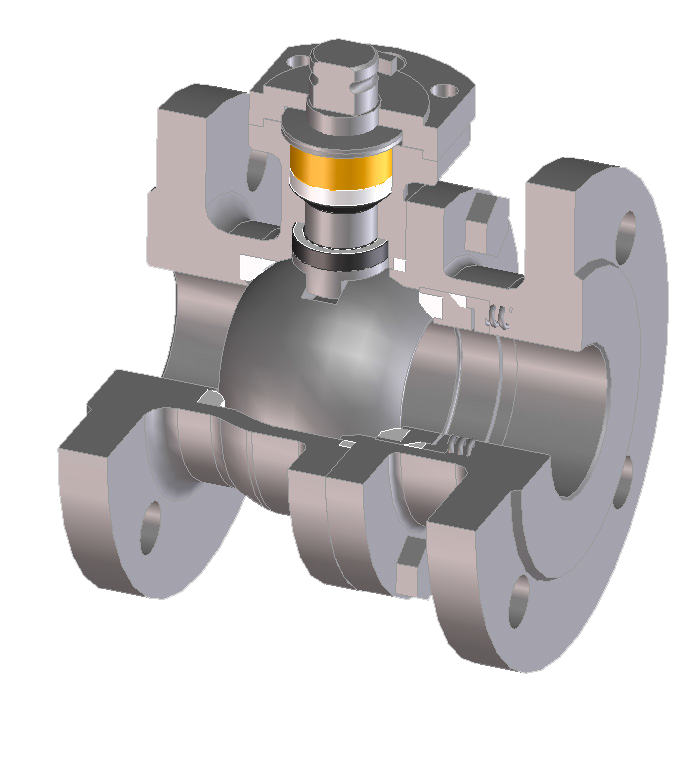

Double Packing & Double Stem Sealed Ball Valves

The FHT 113GL series with spring-loaded seated ball valves represents the evolution in floating ball valve design, incorporating a spring-loaded seating system that ensures perfect sealing regardless of the pressure in line. This innovative technology overcomes the limitations of conventional valves, offering superior performance in critical conditions, from vacuum applications to systems with abrupt temperature changes.

Specialty Valves for Demanding Conditions

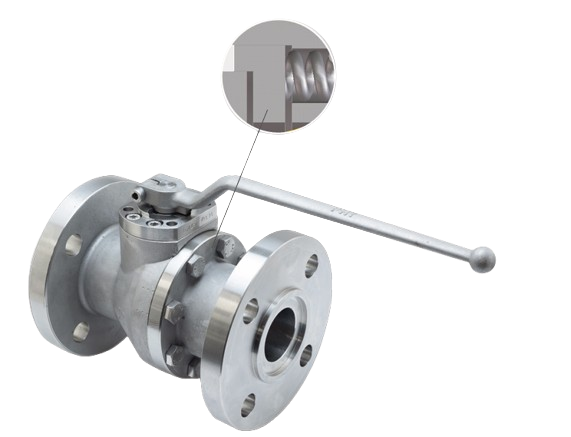

Cavity filler ball valves

100% made in Europe

Ball valves designed and manufactured under the highest quality standards, these valves have international certifications that guarantee their performance, durability and safety in the most demanding applications.

Advantages of Ball Valves with Spring-Loaded Seats

Automatic Depressurization of the Cavity

It automatically releases the excessive pressure accumulated in the internal cavity when the valve is in closed position, avoiding overpressure due to temperature changes and protecting the internal components.

Bidirectional Design

The FHT 113GL valve is fully bi-directional, allowing flow in both directions without loss of efficiency. This reduces cost and complexity by eliminating the need to install two separate one-way valves.

Reliable Low Pressure Sealing

Unlike conventional floating valves, the springs ensure constant contact between the ball and seats, regardless of system pressure, making them ideal for vacuum or low pressure applications.

Better resistance to thermal variations

The spring system automatically compensates for thermal expansion and contraction, preventing leakage in applications with sudden temperature changes, a critical factor in chemical industries and thermal processes.

Supported Ball Design

The spring system in the seats provides constant support of the ball, guaranteeing a perfect seal without depending on the existing pressure in the line.

Reduced Wear and Longer Life

Uniform contact between seats and ball reduces premature wear caused by uneven pressure or fluid vibration, significantly extending valve life.

Torque Stability

FHT’s unique design achieves stable operating torques despite large thermal differences in the fluid, facilitating manual or automated operation.

Improved Performance with Contaminated Fluids

The springs help prevent suspended solids from generating micro-spaces between the ball and seats, minimizing leakage in fluids with impurities or suspended particles.

Why choose FHT?

Manufacturers of quality ball valves

The FHT 113-GL valve design has been specifically developed to overcome the most demanding challenges in the industry. Our spring balanced seat technology offers optimal solutions for conditions where other conventional valves fail.

Low pressure or vacuum applications

Thanks to the springs that maintain constant contact between ball and seats, ensuring a hermetic seal even in the absence of fluid pressure.

Processes with sudden temperature changes

The spring system automatically compensates for the expansion and contraction of the components, maintaining watertightness at all times.

Fluids with suspended solids or particles

Constant spring pressure prevents particles from getting between the ball and seats, reducing wear and leakage.

Low torque operations

The optimized design reduces friction and facilitates manual or automated operation, saving energy and extending actuator life.

ONLINE BUDGETS AND INFORMATION

Do not hesitate, we solve any doubt and quote any order.

We will respond in less than 24 hours.