In the industrial world, where fluids are handled at high pressures and temperatures, safety is undoubtedly the top priority. At FHT Valves, we understand that every component in an industrial system plays a crucial role in protecting facilities, the environment, and most importantly, human lives. This is where Emergency Shutdown Valves (ESD) stand out as a fundamental element.

What are shutdown valves?

Emergency shutdown valves, also known as emergency stop valves, are critical devices designed to quickly and safely interrupt the flow of a medium (gas, liquid, or vapor) in emergency or hazardous situations. Their main purpose is to isolate part of a process or an entire system to prevent or mitigate catastrophic incidents such as leaks, explosions, fires, or overpressure.

Imagine a chemical plant where a process goes out of control and the pressure starts rising dangerously. In this scenario, an ESD valve will act automatically, shutting off the flow to prevent a possible explosion. Their ability to operate autonomously—activated by sensors or control systems—makes them an indispensable part of modern industrial safety protocols.

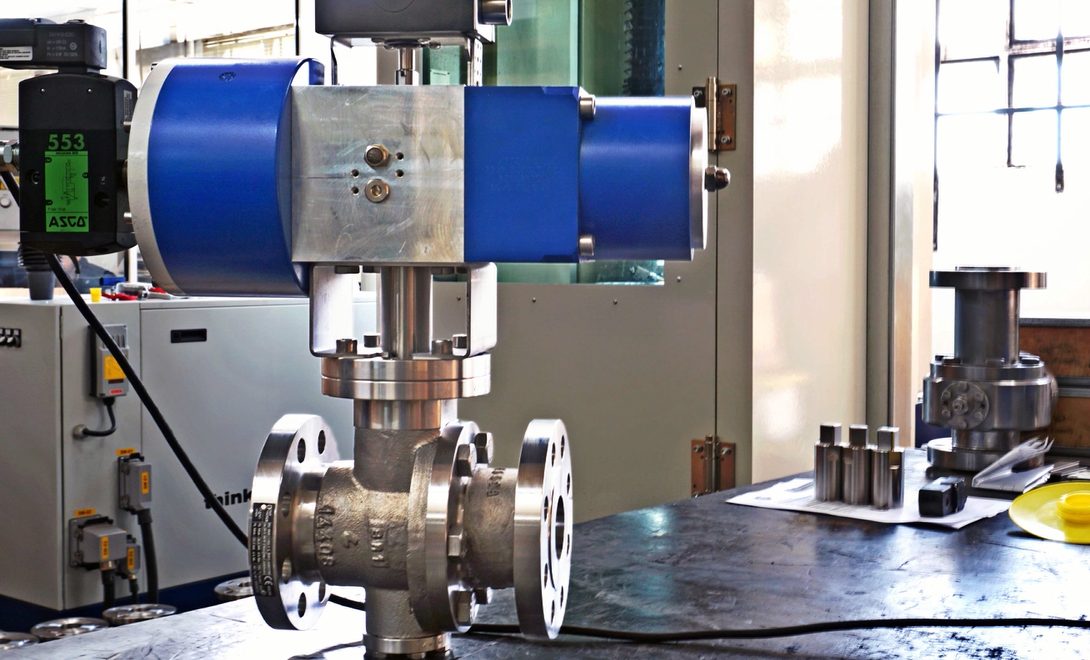

ESDV Emergency ShutDown Valve Actuator testing

How do ESD valves work?

The operating principle of an ESD valve is simple yet extremely effective: detect, activate, and isolate.

- Detection: Sensors distributed throughout the plant constantly monitor critical parameters such as pressure, temperature, flow, or fire detection.

- Activation: If these sensors detect an anomaly exceeding preset safety limits, they send a signal to the Safety Instrumented System (SIS), which in turn activates the ESD valve.

- Isolation: The ESD valve quickly closes, cutting off the flow of the hazardous medium. Many ESD valves are designed to be “fail-safe,” meaning that in the event of a power or control air loss, the valve automatically moves to a safe position (typically closed). This can be achieved through a spring mechanism that compresses to close the valve or, in some cases, through a fusible link that melts at high temperatures, triggering the shutoff.

Key Advantages of FHT Valves’ ESD Valves

Our ESD valves are designed and manufactured to deliver maximum performance under the most demanding conditions:

- Rapid response: Our ESD valves are designed to shut off in a matter of seconds, minimizing the risk of spills, explosions, or environmental contamination.

- Automated operation: They eliminate the need for manual intervention during crises, reducing human error.

- Durability in extreme environments: Made from high-quality materials and resistant coatings (such as epoxy or Inconel), we ensure long service life even under extreme temperatures or corrosive conditions.

- Compliance with safety standards: Our valves comply with the strictest international regulations, such as EN 161, API 6D, and SIL 3 certifications, which are essential for industries like oil and gas.

- Minimal maintenance: Their robust design and self-diagnostic functions reduce downtime and lifecycle costs.

- Rigorous testing: Like all our valves, 100% of them are tested. Even when EN 161 certification is required, the valve closing time is precisely measured to avoid any danger.

Common Applications of ESD Valves

ESD valves are essential across a wide range of industries, including:

- Oil and Gas: Pipelines, refineries, offshore platforms.

- Chemical and Petrochemical Plants: Reaction processes, hazardous product storage.

- Power Generation: Thermal power plants, nuclear facilities.

- Pharmaceutical Industry: Processes involving volatile or toxic substances.

- Water Treatment: Supply and sanitation systems.

At FHT Valves, we are committed to providing emergency shutdown valve solutions that not only meet but exceed expectations for safety and reliability. Our expertise and focus on innovation allow us to offer valves that are true safeguards for your operation.